The Right Dose Featured Signal of Change: SoC863 April 2016

SoC806 — Developments in Drug Delivery explores new technologies that help pharmaceutical firms make drugs that more precisely deliver an exact dose of medicine and reduce instances of patients' missing doses of self-administered drugs. Overdosing is also a problem. Whether accidental or deliberate, overdosing costs lives and adds financial costs in the health-care system. New technologies can help address these issues. Improving the precision of drug delivery and preventing the administration of incorrect doses have obvious health benefits and can reduce costs within the health-care system.

Modifying the properties of pills is becoming easier.

Ibuprofen is an analgesic in common use to help reduce the inflammation and pain resulting from minor injuries; however, ibuprofen can cause harm in large doses, and some people experience upset stomach after taking ibuprofen orally. Researchers from the University of Warwick and the university's spin-off bioadhesives company Medherant (both Coventry, England) have developed a wearable patch that delivers ibuprofen through the skin. This transdermal delivery of ibuprofen could be safer and more effective than oral delivery, and it will not cause the upset stomach that oral delivery often does. The patch relies on a polymer matrix that contains a large dose of ibuprofen that releases steadily for a 12-hour period. The Medherant researchers intend to make the patch commercially available over the counter within two years.

Each year, tens of thousands of people in the United States die from overdosing on opioid painkillers, and millions more suffer from the effects of addiction to these drugs. Pharmaceutical firm Egalet Corporation (Wayne, Pennsylvania) is taking a novel approach to prevent the abuse of opioid painkillers: The company is developing a pill that is essentially indestructible. Many people who abuse painkillers crush the pills into a snortable powder or melt the pills into an injectable solution. Egalet's premise is that preventing people from breaking down pills will decrease the likelihood that the drugs will see use in unsanctioned ways. Hammers, coffee grinders, and blenders cannot crush the pills, and attempts to dissolve the pills will turn them into a foul-smelling gelatinous mush that will not fit into a syringe. To make its pills uncrushable, Egalet uses an injection-molding process and special digestible polymers. Although this new pill-manufacturing method's primary focus is on preventing painkiller abuse, it could also prevent painkiller misuse. For example, some people break or cut their pills to reduce the drug dose (often in attempts to minimize side effects) or to stretch out a prescription. Using drugs incorrectly can lead to health complications, and Egalet's robust pills will thwart attempts at such tampering.

Modifying the properties of pills is becoming easier thanks to the ongoing rapid development of 3D-printing technology. In late 2015, Aprecia Pharmaceuticals Company (Langhorne, Pennsylvania) became the first company to attain US Food and Drug Administration (FDA; Silver Spring, Maryland) approval for commercial use of a 3D-printed pill. The drug—levetiracetam, branded as Spritam—controls epileptic seizures. Aprecia uses its 3D-printing-based ZipDose drug-formulation platform to create the pills. The ZipDose platform creates solid yet highly porous orally disintegrating pills by binding together several layers of medication powder with a water-based liquid. The high porosity of the pills enables the pills to disperse rapidly on exposure to liquid. Aprecia claims that the high-dose Spritam pills dissolve in seconds when a person takes them with a liquid. In addition, the ZipDose platform enables the integration of flavor-masking agents into the pills, which makes the pills palatable. At present, Aprecia is using the ZipDose platform to mass manufacture only Spritam, but the company is investigating additional product candidates for the 3D-printing-based platform. Conceivably, the use of 3D-printing technologies in the pharmaceuticals industry could enable customized dosing and a variety of other configurable properties.

PharmRight Corporation (Charleston, South Carolina) has created Livi–a medication-dispensing device that can help users adhere to their medication regimens. The device, which resembles a pod coffeemaker, holds a 90-day supply of as many as 15 types of pills and uses audio and visual alerts to tell users when and how to take their medications. The device is programmable via a web interface or mobile app, and designated caregivers receive text-message or email alerts if a user misses a dose. The company seems to be marketing the Livi toward elderly people, who are more likely than young people to be reliant on several types of medication.

Proteus Digital Health (Redwood City, California) also offers a system that can help users adhere to medication regimens; however, Proteus's system is much more complex than PharmRight's Livi device. Proteus's main product is a minute ingestible sensor that can integrate into pills or other ingestible products. The sensor pairs with a wearable patch that uses Bluetooth to relay information from the sensor to a smartphone app. Like Livi, Proteus's system provides physicians and caregivers with verifiable data about when a person under their care takes his or her medications. The ingestible sensor received FDA approval in 2012; in July 2015, the FDA sanctioned the use of the sensor as an aid in measuring medication adherence. Predicting whether Proteus's system will see wide rollout is difficult. The system relies on an additional device as well as patient adherence to wearing a patch. The system requires users to swallow a sensor, wear a patch, and use a smartphone app; however, the system's benefits may be strong enough to persuade users to put forth all the necessary effort. Researchers at Purdue University (West Lafayette, Indiana) are also pursuing an electronic approach and fabricated an electronic pill that delivers drugs deep inside the gastrointestinal tract. Delivering medications to the large intestine is difficult because the body often absorbs or metabolizes the drugs before they reach their target destination. The researchers' pill consists of a sealed drug chamber and electronic components that activate and open the drug chamber in response to proximity to a magnet. The researchers suggest that their technology could help sufferers of Clostridium difficile and other intestinal problems by delivering powdered microbes directly to the target location.

Another development could help elderly people and others who suffer from debilitating conditions such as arthritis. Researchers from North Carolina State University (Raleigh, North Carolina) and the University of North Carolina at Chapel Hill (Chapel Hill, North Carolina) are developing a stretchable-elastomer drug-delivery system—essentially a medication-loaded adhesive-strip-type device. The novel part of the system is its reliance on capsules that contain medication-loaded nanoparticles. The nanoparticles slowly release medication into the capsules; when the wearer moves, the elastomer stretches, which compresses the capsules, causing them to dispense medication into the wearer's skin. In practice, a person with arthritis would receive small doses of a painkiller when he or she moves. The more a wearer moves, the more medication he or she receives from the device.

The Development of this Signal of Change

Data Points

- SC-2016-03-02-021

Researchers at the University of Warwick have worked on a new patch-delivery system that contains sufficient quantities of ibuprofen to release steadily over 12 hours. - SC-2016-03-02-031

To prevent abuse of opioid painkillers pharmaceutical firm Egalet Corporation has developed indestructible pills. - SC-2015-11-04-030

Aprecia Pharmaceutical gained US Food and Drug Administration approval for commercial use of its 3D printed pill technology to make the bottom part of the pills more porous to help accelerate dispersion in the body.

Implications

The Right Dose

Improving the precision of drug delivery and preventing the administration of incorrect doses have obvious health benefits and can reduce costs within the health-care system.

Previous Alerts

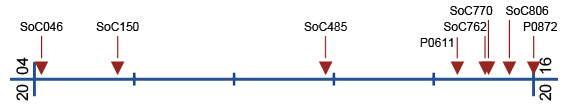

- SoC046 — The End of Actuarial Medicine? (March 2004)

The health-care industry is currently anticipating two new sources of data to supplement historical data. The first concerns customization of health-care solutions on the basis of individuals' genetic profiles. The second is the predictive capabilities of the patient's genome. - SoC150 — Toward Customized Medicine (January 2006)

As scientists continue their pursuit of customized medicine through research in molecular biology and genetics, the broader social community is beginning to recognize and address infrastructure, regulatory, and policy needs and issues. - SoC485 — Better Medicine: Conflicting Approaches (January 2011)

Improving medicine's performance and administration to better patient outcomes appears to follow two—potentially conflicting—roadmaps, and advances occur on both fronts. - P0611 — Medication in Transition (March 2014)

Advanced methods of administering and distributing medication are emerging; nanotechnology plays a role in many of these new approaches. - SoC762 — Health-Care Devices to Stick On (November 2014)

Efforts to develop stick-on health-care devices are manifold. - SoC770 — Implantable Health-Care Devices (December 2014)

Implantable sensors that enable continuous, uninterrupted monitoring of data likely will play a more important role in the future. - SoC806 — Developments in Drug Delivery (June 2015)

Novel drug-delivery technologies offer a wide range of benefits. - P0872 — Data-Mining Science (January 2016)

Attachable and implantable devices could change the nature of health care by providing nonstationary options for continuous diagnostic testing and treatment.