Materials by Design Featured Signal of Change: SoC1051 November 2018

SoC1046 — Understanding Materials from October 2018 discusses how scientists are making use of new computational capabilities to investigate existing knowledge and to develop methods for gaining additional materials-science insights. Understanding materials and creating materials are related activities, but they present very different challenges. Traditional materials development is a slow process in which scientists go through many rounds of synthesizing materials, testing the materials' properties, and matching the materials to needs. Data-driven materials development accelerates the creation of materials by mining databases to discover and predict candidate materials that might match a particular application. For example, the US Materials Project (https://materialsproject.org), which is operated by the Lawrence Berkeley National Laboratory (US Department of Energy; Washington, DC), and the European Novel Materials Discovery Laboratory (https://nomad-coe.eu) support related activities. But many other efforts to develop data-driven approaches to materials development are under way. Artificial intelligence (AI) and machine learning (ML) are common features of these approaches.

Many companies are sitting on a vast amount of materials data but lack the tools necessary to make full use of it.

Researchers are increasingly demonstrating the ability of computational techniques to accelerate the discovery of materials that have the properties necessary to meet a specific need. However, computational techniques often provide little insight into the ease with which researchers can synthesize a target material. Researchers often use trial and error to develop the appropriate synthetic techniques for creating a new material (regardless of whether computation or manual human effort is responsible for the material's design). Materials fabrication is another field of materials science that is open for automation. Research could pave the way for programs that not only discover new materials but also provide researchers or manufacturers with recipes for fabricating them, thereby accelerating materials development and commercialization.

The US Department of Defense's (Arlington County, Virginia) Defense Advanced Research Projects Agency (DARPA; Arlington, Virginia) is working on Make-It—a program that is looking at the use of AI to automate the discovery of small molecules and their syntheses. Researchers are attempting to "provide the foundational technologies required to transform synthetic chemistry to an information-centric science" (www.darpa.mil/program/make-it). The Massachusetts Institute of Technology (MIT; Cambridge, Massachusetts), SRI International (Menlo Park, California), and Grzybowski Scientific Inventions (Merck Group; Darmstadt, Germany) are participating in the four-year program.

And a team from the US Department of Energy's (Washington, DC) SLAC National Accelerator Laboratory (Menlo Park, California), which Stanford University (Stanford, California) operates; the National Institute of Standards and Technology (NIST; Gaithersburg, Maryland); and Northwestern University (Evanston, Illinois) used ML in combination with a rapid material-testing technique to evaluate many possible formulations of metallic glass very quickly. The team created a metallic glass that is as strong and light as steel and is also resistant to corrosion and wear. The researchers hope that such an ML-based approach will enable scientists to scan samples of hundreds of materials within a very short period and receive almost instant feedback so that another set of materials can go through scanning the very next day. Such an approach could substantially accelerate materials discovery and evaluation.

Scientists at MIT's Computer Science and Artificial Intelligence Laboratory (www.csail.mit.edu) developed a system to specify the properties the scientists want a material to have. The system then creates a microstructure of the material in line with the scientists' specifications. In the past, researchers had to identify a biological material with the qualities they wanted—for example, the toughness of bone—and then reverse engineer the material. When they had an idea about what the material's microstructure was like, they would try to come up with a human-made material with such a microstructure. With the new system, "designers numerically specify the properties they want their materials to have, and the system generates a microstructure that matches the specification" ("Automating materials design," MIT News Office, 2 February 2018; online).

Applications of such systems already exist. For example, Stanford University assistant professor of materials science and engineering Evan Reed used ML to develop new electrolytes for lithium-ion batteries. And University of Maryland, College Park (College Park, Maryland), research scientist Valentin Stanev and colleagues have used ML in superconductor research. Some scientists believe that big data and AI might enable materials by design—a semiautomated materials-development approach that matches materials with necessary properties. Dr. Reed outlines the possibility: "Imagine that you need a battery that has a certain set of properties. You feed those into the machine learning model that then automatically runs through all available, known materials and suggests a range of batteries consisting of different materials that meet your specifications" ("The Wild New Materials of the Future Will Be Discovered With AI," Singularity Hub, 22 March 2018; online).

Data science is emerging as an important field that can facilitate developers' design of materials. It will also help to optimize industrial-scale manufacturing processes. Today, many companies are sitting on a vast amount of materials data but lack the tools necessary to make full use of it—materials data are only as good as a human's ability to use and interpret them. Emerging tools will not only help scientists learn about and understand materials but also guide future manufacturing processes to improve components and products. New applications will emerge, costs could come down, and research-and-development speed could accelerate.

Materials-by-design research is ongoing in academia, government, and industry. Much of the research concentrates on developing AI-enabled simulation tools that facilitate the materials-discovery and materials-design processes. However, today's simulation tools have limitations in the range and complexity of nanomaterial systems that they can handle. Nevertheless, as AI-enabled technologies develop, research teams will continue to turn to advanced techniques and technologies that will aid in accelerating the process of understanding fundamental relationships between nanomaterials and their properties.

The Development of this Signal of Change

Data Points

- SC-2018-09-05-062

The Defense Advanced Research Projects Agency is working on a program that is looking at the use of artificial intelligence to automate the discovery of small molecules and their syntheses. - SC-2018-07-11-075

A team from the SLAC National Accelerator Laboratory, the National Institute of Standards and Technology, and Northwestern University used machine learning in combination with a rapid material-testing technique to evaluate many possible formulations of metallic glass very quickly. - SC-2018-06-06-026

Scientists at the Massachusetts Institute of Technology's Computer Science and Artificial Intelligence Laboratory developed a system to specify the properties the scientists want a material to have.

Implications

Materials by Design

Data-driven materials development accelerates the creation of materials.

Previous Alerts

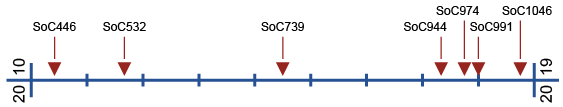

- SoC446 — Harnessing Living Materials (June 2010)

Researchers are now beginning to develop what could become an entirely new class of materials and technologies with dynamically adaptive properties by harnessing living organisms and biological materials. - SoC532 — A New Age in Materials (September 2011)

Materials technology is changing rapidly—not only materials under development in laboratories, but also materials in use in commercial applications. - SoC739 — Healing Materials (July 2014)

Several recent developments in smart materials concern an interesting group of materials with healing functionalities. - SoC944 — Exploring Biobased Materials (May 2017)

A growing number of companies are embracing the use of biobased materials in their products and even changing the types of biobased materials they use. - SoC974 — Toolboxes for Materials Innovation (October 2017)

New approaches look at creating general frameworks, comprehensive tool kits, and holistic concepts that can help scientists and product developers create and choose appropriate materials for given use cases. - SoC991 — Self-Assembly and Self-Adaptation (January 2018)

The approaches this Signal of Change presents enable objects and components to interact with materials or the environment in such a way that the objects' use potential and functionalities change. - SoC1046 — Understanding Materials (October 2018)

Scientists make use of new computational capabilities to develop methods to gain additional materials-science insights.